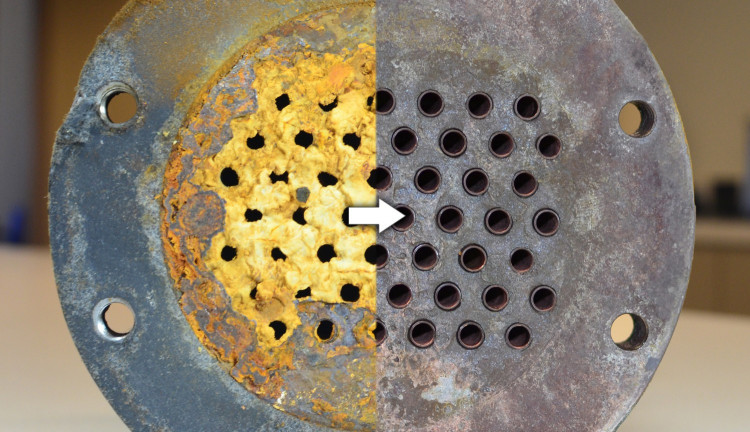

Have you been plagued by scales? We have a new solution for you.

Morko (manufacturer) noticed early on the various problems caused by scale, which can be found in many industrial sites, and poured all of its efforts into R&D in order to find a powerful solution by utilizing an ultrasonic approach. The USP (Ultrasonic Scale Preventer) was developed and produced as a result of enormous efforts that were undertaken by the Morko engineering team.

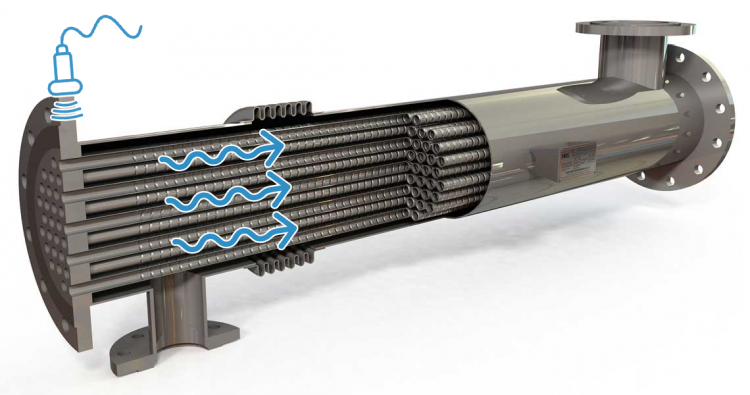

Morko (manufacturer) noticed early on the various problems caused by scale, which can be found in many industrial sites, and poured all of its efforts into R&D in order to find a powerful solution by utilizing an ultrasonic approach. The USP (Ultrasonic Scale Preventer) was developed and produced as a result of enormous efforts that were undertaken by the Morko engineering team. The USP of Morko opened a new age for the solution of scale problems with its unique and revolutionary method that uses a completely different approach from current strategies. As this approach is based on the vibration, acoustic streaming and cavitation generated by ultrasonic waves, it is a safe, efficient, and cost-effective solution that is free from the various problems that are usually expected from chemical methods.